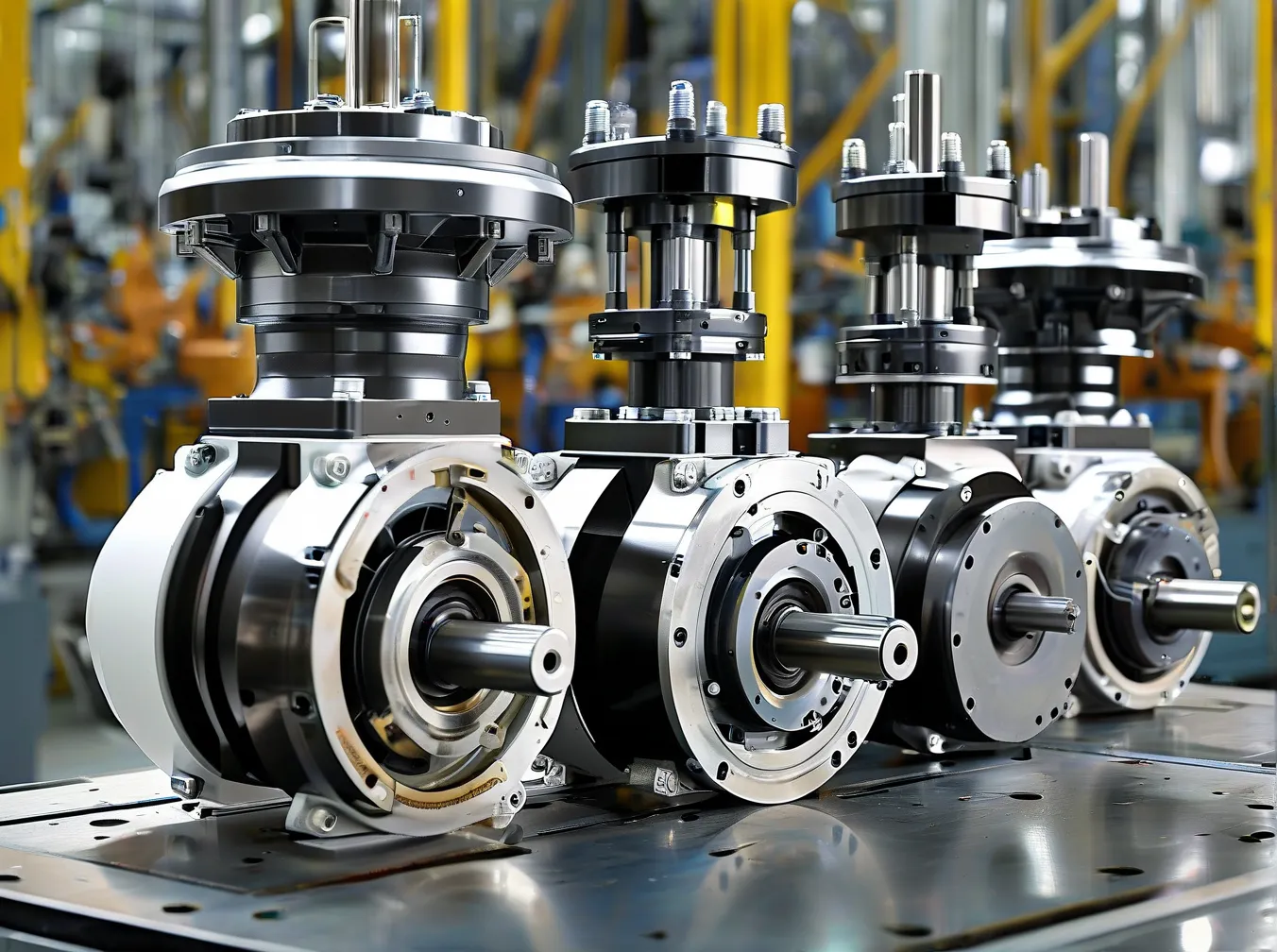

When sourcing OEM motor solutions for industrial applications, the stakes are high. Custom industrial motors power everything from manufacturing assembly lines to renewable energy systems, and selecting the right partner can mean the difference between operational excellence and costly downtime. With over 40% of industrial energy consumption attributed to motor-driven systems (International Energy Agency), optimizing performance and efficiency isn’t just a preference—it’s a business imperative.

Understanding Your Application Requirements

Start by defining your technical specifications with precision. High-performance motors must align with:

– Torque and Speed Profiles: Does your application require constant torque for heavy machinery, or variable speeds for precision tasks like CNC machining?

– Environmental Factors: Will the motor operate in extreme temperatures, corrosive environments, or hazardous locations requiring explosion-proof certifications (e.g., ATEX or IECEx)?

– Energy Efficiency Standards: Compliance with regulations like IE4 or IE5 (International Efficiency classes) can reduce energy costs by up to 30% (ABB Group).

A food processing plant, for example, might prioritize stainless steel motors with IP69K ratings to withstand frequent washdowns, while a mining operation would need motors engineered for dust ingress protection (IP65+) and high shock resistance.

Evaluating OEM Motor Manufacturers: Key Criteria

Not all suppliers deliver equal value. Prioritize partners that demonstrate:

-

Technical Expertise

Look for engineers who engage in collaborative design reviews rather than offering cookie-cutter solutions. Case in point: A leading aerospace manufacturer reduced vibration-related failures by 60% after working with an OEM that performed finite element analysis (FEA) during the prototyping phase. -

Certifications and Testing Protocols

Reputable providers adhere to ISO 9001 quality management systems and provide third-party test reports for critical metrics like thermal performance and harmonic distortion. -

Scalability and Lead Times

Verify production capacity—can the supplier handle both low-volume custom batches and large-scale orders without compromising lead times? Companies like Siemens often leverage modular designs to balance customization with rapid delivery.

The Role of Advanced Materials and Manufacturing Tech

Modern motor performance hinges on material innovation:

– High-Grade Laminations: Amorphous metal cores can reduce core losses by 70% compared to traditional silicon steel (DOE Study, 2022).

– Smart Sensors: Integrated IoT-enabled sensors for real-time monitoring of temperature, vibration, and load conditions are becoming industry standard. A recent McKinsey report notes predictive maintenance capabilities can lower unplanned downtime by up to 50%.

Ask potential suppliers about their adoption of additive manufacturing (3D printing) for complex geometries or vacuum pressure impregnation (VPI) processes to enhance winding insulation longevity.

Navigating Customization Without Over-Engineering

While tailored solutions are valuable, unnecessary features inflate costs. Strike a balance by:

– Requesting value engineering assessments to identify cost-neutral optimizations (e.g., switching from aluminum to composite housings).

– Benchmarking prototypes against existing solutions using lifecycle cost analysis (LCCA). A wastewater treatment plant saved $120k over five years by opting for a slightly more expensive but maintenance-free magnetic bearing design.

Post-Purchase Support: The Hidden Factor in ROI

A motor is only as reliable as its support network. Ensure your OEM provides:

– Localized Service Teams: On-site troubleshooting within 24 hours for critical failures.

– Digital Twin Integration: Access to virtual models for performance simulations and firmware updates. WEG’s digital twin platform, for instance, helped a paper mill optimize motor load profiles remotely, boosting efficiency by 12%.

– Warranty Transparency: Clear terms covering not just defects but also wear-and-tear scenarios common in your industry.

Case Study: Precision Motors in Robotics Automation

When a robotics integrator needed compact motors with zero-backlash for surgical robots, their OEM partner developed a frameless direct-drive solution using Halbach array magnets. The result? A 25% reduction in weight and sub-arcminute positioning accuracy—achieved through iterative CFD simulations and material stress testing.

Final Checklist Before Partnering with an OEM Motor Supplier

- Validate application-specific testing data (efficiency curves, duty cycle ratings).

- Audit manufacturing facilities—either virtually or through third-party reports like UL certifications.

- Compare total cost of ownership (TCO), not just upfront pricing. A $5k premium on a high-efficiency motor could yield $50k in energy savings over a decade.

By prioritizing technical alignment, innovation transparency, and lifecycle support, you’ll secure OEM motor solutions that drive productivity long after installation—turning a procurement decision into a strategic advantage.

Leave a Reply